The demands on your production are continually increasing. As a solution provider, we therefore focus entirely on your needs. Continually providing increased efficiency, reliability and quality: we know what today’s metal processing industry requires from you – with our new, flexible ELEMENT platform we are already setting the course for a successful future today.

Apart from the high level of productivity and precision you have come to expect from us, this solution offers customised configuration options and updates, enabling you to respond to future requirements. This gives you a real competitive edge – helping you to stay ahead in the long run.

The ELEMENT 400 is the pioneer of our new platform solution. As a highly flexible all-rounder, it embodies everything it stands for. Safe, efficient, suitable for automation, versatile and upgradable with hardware and software from a single source, it combines our entire experience from more than 120 years in the field of thermal cutting – to benefit you in your everyday work.

The ELEMENT 400 is our multi-talent for all common cutting and additional processes, for serial tasks in continuous operation and special tasks with a focus on perfect cuts.

For More information please click below link

Do you need a compact flat bed cutting machine which can be installed and operated quickly and easily? Are you looking for an economical machine which gives full power in a small area? The MetalMaster 2.0 is the economical entry level machine for simple plasma cuts, just oxyfuel or both combined.

Thanks to the space saving, compact construction the machine can be installed quickly ready for use. High position speeds and a fast, intelligent torch lifter reduces non-productive times.

The user-friendly touch-screen control Global Control 2.0 means you need only 3 clicks from loading the part program to being ready to cut. The free-standing console keeps sensitive electronics away from the heat and dust of cutting.Through our safety concept the productivity and flexibility will be increased: the on-board light barriers make it possible to clear the table during cutting. We will still stay in contact with you after commissioning: QR codes on the control console link you directly to the Messer support network if necessary.

For More information please click below link

https://in.messer-cutting.com/products/machines/metalmaster-20

MultiTherm Pro is the latest offering from Messer.

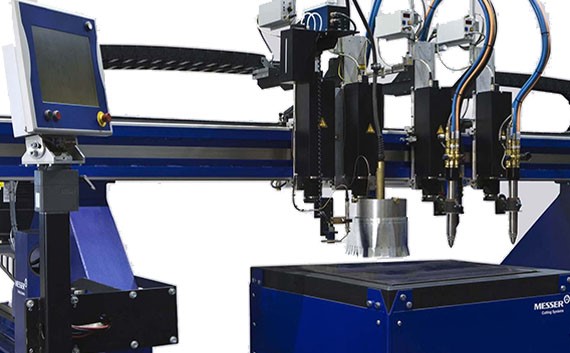

Its Industry 4.0 Ready and it helps to achieve higher productivity with 24 m/min positioning speed and Acceleration 0.04g. High accuracy with Digital AC Servo motor & planatory gear box. MultiTherm Pro has robust gantry with LM guides in Y-axis ensures stable and reliable cutting. MultiTherm Pro is compatible for compact Plasma bevel head (Bevel R) for weld preparation parts. The user-friendly control Global Control speeds set-up and reduces errors and non-productive times. Patented ALFA torch for oxy-fuel cutting, comes with quick nozzle change for higher productivity. The efficient design of the wheel-housing combined with positive longitudinal drives ensure high stability.

For More information please click below link

https://in.messer-cutting.com/products/machines/multitherm-pro

Do you need a compact machine which is flexible and easy to use for your daily work? The MultiTherm® Eco is the perfect universal machine for oxyfuel and plasma cutting. Efficient cutting productivity due to a high level of automation and easy set-up and operation produces quality components - quickly and efficiently

The user-friendly CNC control Global Control speeds set-up and reduces errors and non-productive times.The intelligent torch lifter SL200 for plasma allows time-saving cycles and high stroke speeds. Multiple ALFA torches with quick nozzle change permit high productivity.

The symmetric wheel-housings and parking space for temporarily unused heads optimise the working width but keep space requirements reasonable. The combination of oxyfuel and plasma cutting processes cover all commonly occurring materials and tasks. The MultiTherm® Eco impresses with high dynamic and is suitable for bevel cutting.

For More information please click below link

https://in.messer-cutting.com/products/machines/multitherm-eco

Messer CraftBlade CNC has been developed bringing in 120 years of Messer experience in handling all the basic cutting needs in the smaller plate formats which can be used for training and producing small thermally cut parts.

CraftBlade is technologically a superior product, professionally designed and engineered meant to make the plate cutting task simplified, affordable and easy to learn.

Innovative design reduces the footprint of the machine as there are no optical tracing zones and retracting arms.

It is to make the plate cutting task simplified. The thoughtful design makes it easy to install and use. Principally Equipped with Messer oxyfuel cutting system produces high quality cut parts , it can be easily modified to use plasma system as well so the learning and usage can be versatile.

It is not only saving the cost on installation and usage but is extremely convenient as well. This unique package allows you to replace old setups like optical and template cutting machines or start a new plate cutting setups without using high capital investment and workshop floor space. The machine with gas setup can be easily upgraded to plasma.

Lowest investment, installation, maintenance and running cost makes it deliver lowest cutting cost per piece for training and industrial use.

For More information please click below link

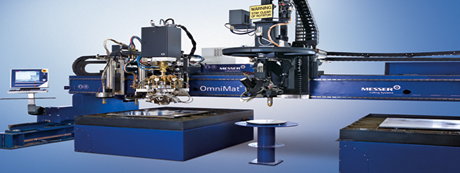

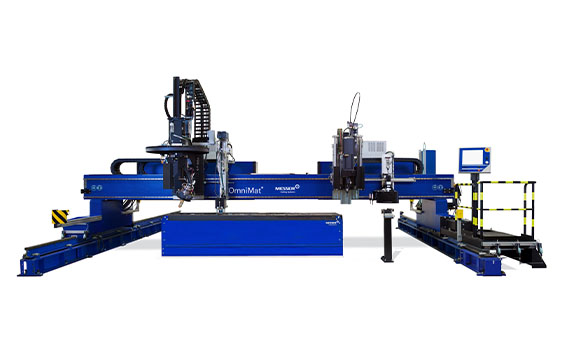

Are you engaged in shipbuilding or heavy engineering? The OmniMat® is characterised by a particularly high ability to handle heavy loads and high productivity. Whether oxyfuel, underwater or dry plasma, whether vertical or bevel cutting or with drilling, the OmniMat® is the ideal solution for the largest working areas and the toughest production conditions. A full spectrum of marking processes is, of course, also available.

OmniMat® is a large size CNC cutting machine with a heavy-duty structure and multi axis control, suitable for a wide field of applications and complicated cutting jobs. A number of different torch suspensions with tool holders is available, e.g. marking tools, punching and drilling devices, strip cutting attachments, triple torch or rotating triple torch, plasma arc contour bevel unit. The CNC cutting machine has a sturdy portal design, positive bilateral longitudinal drives and a precise machine guiding profile, providing you high cutting accuracy and contouring precision.

Whether you want to cut with oxy-gas, underwater or dry plasma, whether straight cuts or weld preparations, the OmniMat® offers you the ideal solution. The patented Global Rotator®, equipped with advanced 5 axis robotic compound movement control technology, is ideally suited for "V" & "Y" contour bevelling with only one pass. This greatly reduces fabrication time and milling after the cutting process is now superfluous.

The system is now widely used in industries such as shipbuilding, heavy industry, engineering equipment, etc.

For More information please click below link

For More information please click below link

Newly Developed state of art, affordable CNC profile Cutting system. Terra Blade a popular CNC Profile cutting machine, is idealy suited for small and medium production companies to take control of their production by doing their own steel profile cutting in house. Equipped with simple, easily operatable gas console supplemented with MS 932 torch & its quick change nozzles ensure high quality gas cutting. Ideally suited for Variety of plasma system increase the scope of applications. Extremely stable & reliable German technology at Indian price.

We are occupied with offering TerraBladeD Messer’s best profile cutting machines, which are accessible in different sizes and details to provide the requests of customers. Perfect for little scale business or workshops, these machines are sturdy and light weight. These are utilized crosswise over different businesses for number of utilizations.

For More information please click below link

https://in.messer-cutting.com/products/machines/terrablade-d

Innovative models with unique processes, combining high-precision plasma bevel cutting, high-speed drilling, tapping, milling and other functions on the same equipment. PLAMill GV is the machine which perfect combination of high running speed and high processing efficiency.

For More information please click below link

Gas and plasma cutting CNC

It is a large size CNC laser cutting machine with a heavy-duty structure and precise machine guiding profile and provides high cutting accuracy and precision contouring suitable for a wide field of applications and complicated cutting jobs.

The plasma / fiber laser combination cutting on the same part will increase productivity by allowing critical internal features to be cut with the fiber laser and external features to be cut with the plasma torch without moving the part to another piece of equipment.

For More information please click below link

https://in.messer-cutting.com/products/machines/omnimat-combo

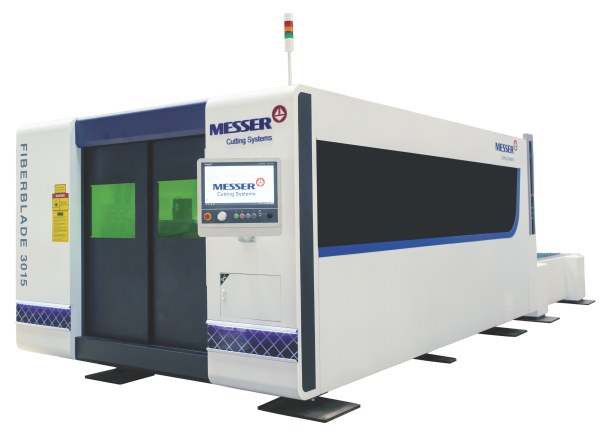

OmniMat Fiber is an ideal machine for laser cutting in large working areas. It is a large size CNC laser cutting machine with a heavy-duty structure and precise machine guiding profile and provides high cutting accuracy and precision contouring suitable for a wide field of applications and complicated cutting jobs. The system is now widely used in industries such as heavy industry, engineering equipment, etc.

For More information please click below link

https://in.messer-cutting.com/products/machines/omnimat-fiber

FiberBlade V, the new fifth generation high speed laser cutting machine, benefiting from Messer’s high speed cutting technology, can achieve top level productivity in the industry. It is simple and user-friendly HMI helps operator to produce high quality products after short-term training.

For More information please click below link

https://in.messer-cutting.com/products/machines/fiberblade-v

Compact design reduces space requirements. The machine is equipped with scan cut feature for maximum utilisation making the cutting operation economical

For More information please click below link

Fiber laser cutting CNC