Manufactured to the highest standards, genuine Hypertherm torches and consumables enhance cut quality, extend consumable life, and boost productivity – at the lowest possible operating cost.

The only real bargain is real value. Using genuine Hypertherm consumables for your Hypertherm plasma cutting system is the only way to ensure optimal performance.

Here’s why:

Patented Technologies – Every day, Hypertherm engineers are working on new ways to improve the plasma cutting process. Thousands of hours of engineering time focused solely on plasma consumable technology guarantees the best possible cutting performance from your system.

Synergistic design – Hypertherm systems and consumables are designed to work together. System features and consumable designs are matched to optimize performance and reliability – to give you the best possible cut, over the longest service life.

Critical to function engineering – Hypertherm engineers identify the critical features of each consumable part that will have an impact on cutting performance, and design accordingly. The specifications for these features are held to tolerance ranges that exceed even Six-Sigma quality standards.

Highest quality – Investments in the most current quality systems, state-of-the-art manufacturing facilities and intensive machine operator training ensure that every consumable part that you receive from us will perform to your highest expectations

The HyPerformance® HPR400XD plasma system has been designed and built for maximum performance and productivity in x-y, bevel and robotic cutting operations. The versatile 400-amp rated system combines fast cutting speeds, rapid process cycling, quick changeovers and high reliability, and delivers the ultimate in HyPerformance mild steel cutting, plus aluminum capability and unmatched stainless steel cut quality.

Designed especially for your HyPerformance® HPR XD® plasma system, the Hypertherm preventive maintenance kit contains all the necessary parts you need to keep your system operating at peak performance.

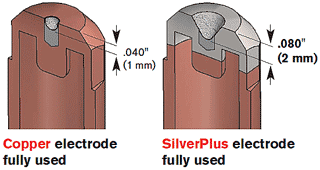

SilverPlus® electrodes incorporate a hafnium/silver interface at the point of electrical transfer. The hafnium/silver extracts more heat and has a stronger bond than hafnium/copper.

The result: dramatically longer electrode and nozzle life – increasing productivity and lowering operating costs by reducing the number of consumable sets used and changeouts.

Protect your investment. Choose genuine Hypertherm torches and consumables to keep your system running at peak performance. Incorporating the latest technologies and manufactured to the highest standards, Hypertherm consumables enhance cut quality, extend consumable life, and boost productivity.

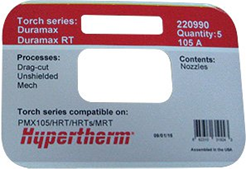

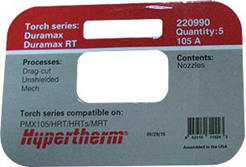

Duramax® HRT handheld and Duramax MRT machine retrofit torches

Powermax600

Powermax800

Powermax900

MAX42/43

Duramax® HRT handheld and Duramax MRT machine retrofit torches

Powermax1000

Powermax1250

Duramax retrofit torches provide improved performance, longer consumable life and better system performance for older Powermax and MAX systems.

Powermax1650

RT80 retrofit torch upgrade

Powermax1100

Today’s plasma systems can produce exceedingly nice cut parts with little or no post-production processes. Yet, a plasma system is only as good as the consumable parts in the torch. Purchase knock-off (sometimes called after-market) consumables and your system’s performance could suffer.

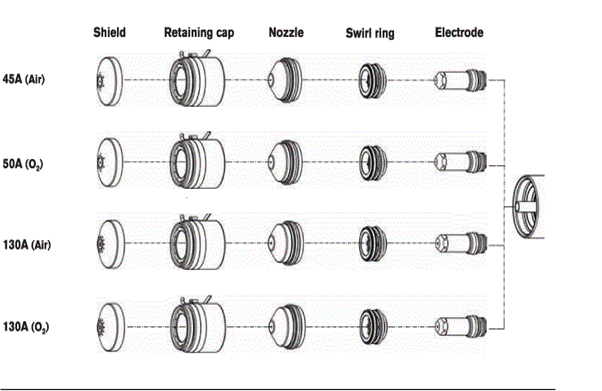

The HySpeed® Plasma HSD130 is positioned between Powermax air plasma and HyPerformance HyDefinition plasma systems. It features impressive cut speeds, rapid piercing and minimal secondary operations for maximum productivity. A cost-effective alternative to other metal cutting solutions such as oxyfuel or air plasma, the system incorporates Hypertherm’s patented LongLife™ technology to significantly improve consumable life for both oxygen and air processes

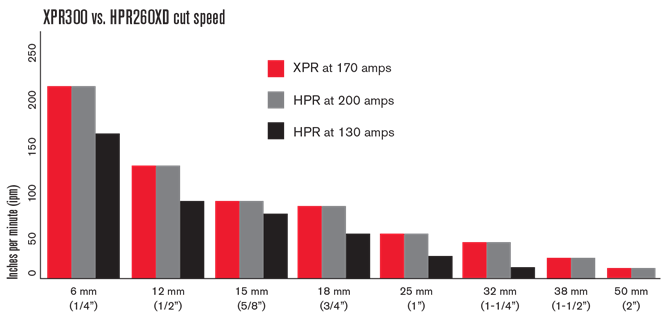

The new XPR300® represents the most significant advance in mechanized plasma cutting technology, ever. This next generation system redefines what plasma can do by expanding its capabilities and opportunities in ways never before possible. With unmatched X-Definition™ cut quality on mild steel, stainless steel and aluminum, the new XPR300 increases cut speed, dramatically improves productivity and slashes operating costs by over 50%. New ease-of-use features and engineered system optimization make the XPR300 easier to run with minimal operator intervention, while also ensuring optimal performance and unmatched reliability.

Counterfeiters are also targeting highly engineered, high-value industrial products, and our industry has not been immune to this growing threat. Plasma cutting consumables - nozzles, electrodes, swirl rings, etc. - are now being seen in all regions. Be alert, be smart, and don’t let counterfeit consumables compromise your work, or your safety.

Counterfeits are usually very close copies of the genuine product, so it is easy enough to be misled, and think you are getting a good bargain. But this is one bargain that can be a major liability to your business.

The answer, of course, is to be alert for counterfeit scams, and to mistrust any consumable offer that sounds too good to be true. Be sure. Only purchase genuine Hypertherm consumables and only through an authorized distributor.

It’s not always easy to spot a counterfeit. Packaging is relatively easy to copy. Quality and performance are not.

To avoid being scammed by counterfeit consumables, here are a few things to watch out for:

A claim of "genuine" consumables from an unauthorized distributor, an unknown agent, or off the internet

Suspiciously low pricing for "genuine" consumables or software, or any offer that sounds too good to be true

Discrepancies in the physical appearance of the label, packaging, or product, compared to that of the original consumable

Poor or inconsistent consumable performance when compared to a genuine product - only 50% of usual service life, for example, or any abnormal signs of burning, metal deformation, etc.

Consumables

Versatile, professional-grade plasma system offers increased cut capacity – up to 16 mm metal – as well as enhanced gouging and marking capabilities.

Highly portable plasma cutting system includes a built-in air compressor, allowing metal cutting anywhere there is single-phase power.

Highly portable two-in-one plasma cutting system provides high-power capability for thick metal cutting, and also enables detailed, thin metal cutting.

Portable, professional-grade 20 mm (3/4”) plasma system maximizes uptime and productivity in handheld and mechanized cutting and gouging operations.

Portable, professional-grade 25 mm (1”) plasma system maximizes uptime and productivity in handheld and mechanized cutting and gouging operations.

Portable, heavy-duty 32 mm (1-1/4") plasma system maximizes uptime and productivity in handheld and mechanized cutting and gouging operations.

Portable, heavy-duty 38 mm (1-1/2”) plasma system maximizes uptime and productivity in handheld and mechanized cutting and gouging operations.

The MAXPRO200® Long Life® air and oxygen plasma cutting system delivers exceptional performance and maximum consumable life for high capacity mechanized and handheld cutting and gouging.

Hand held plasma

HyPerformance plasma systems deliver HyDefinition cut quality at half the operating costs. By incorporating Hypertherm's proven HyDefinition, LongLife, and patented PowerPierce and True Hole technologies, HyPerformance Plasma boosts overall performance, productivity and profitability.

Designed and built for maximum performance and productivity in mechanized cutting operations, the versatile HyPerformance HPRXD plasma system gives you unmatched HyPerformance cut quality from very thin up to mid-range materials.

The new XPR300™ represents the most significant advance in mechanized plasma cutting technology, ever. This next generation system redefines what plasma can do by expanding its capabilities and opportunities in ways never before possible. With unmatched X-Definition™ cut quality on mild steel, stainless steel and aluminum, the new XPR300 increases cut speed, dramatically improves productivity and slashes operating costs by over 50%. New ease-of-use features and engineered system optimization make the XPR300 easier to run with minimal operator intervention, while also ensuring optimal performance and unmatched reliability.

The Powermax® family of products consists of seven highly portable, professional grade air plasma cutting and gouging systems. Built to withstand heavy duty use in demanding industrial environments, the systems are an ideal choice for hand or automated cutting and gouging of any electrically conductive metal; depending on system size, they offer a severance cut capacity from 16 mm (5/8") at 30 A to 57 mm (2-1/4") at 125 A.

The MAXPRO200® LongLife® plasma cutting system is engineered for heavy-duty, high capacity automated and handheld cutting and gouging applications. The easy-to-use system operates with either air or oxygen plasma gas, and combines fast cutting speeds and quick process changes to maximize productivity. Advanced Hypertherm consumable designs – including LongLife® technology –improve cut consistency and significantly increase consumable life to lower your cost per part.

Mechanized plasma