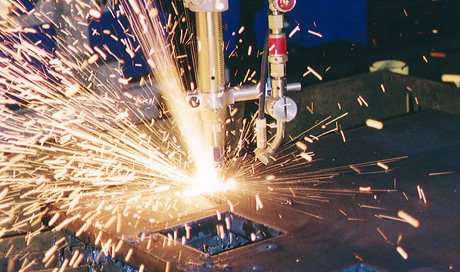

The MS 932 is very versatile. It can be used with all fuel gases and is very safe to operate. The torch design prevents flashbacks even when piercing heavy, thick materials.

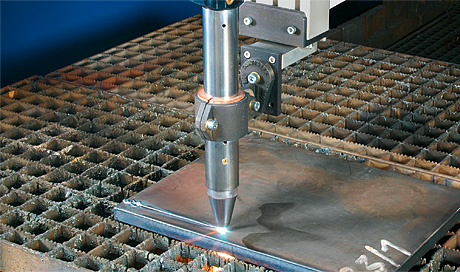

The Messer Cutting Systems globally developed ALFA Oxyfuel torch takes oxyfuel cutting to an entirely new level. The ALFA torch internalizes many features that used to have to be on the outside of an oxyfuel torch, including height sensing and auto-ignition.

The torch nozzle is changed without tools, eliminating the possibility of misaligning the torch, which drastically reduces set-up time. Once the cap is unscrewed, the nozzles are free and can be easily replaced or checked.

There are no sensors to change for different thicknesses of material, and the ALFA torch is able to effectively cut right up to the edge of the plate. Slag, mill scale, and moisture have no effect on the height sensing of the ALFA torch.

The magnetic height sensing is fully integrated into the torch with no external parts. Sensing ring and additional cables are no longer present, so there is no wear of the sensor and no need to change it for different material thicknesses. Better material utilization through better sensing right up to the edge of the plate.

The Sensomat® ALFA height sensing is easy to use with a digital display of the current operating status. With the ALFA torch, fast nozzle change is possible without the use of tools. Set-up times are significantly reduced.

Torches

Nozzles

Rail track with interlocking sections:

length 1200 mm / 47 inches: 716.51790

length 1800 mm / 71 inches: 716.52018

Injector machine cutting torch MSZ 832/110-A for fuel gas acetylene: 716.51787

Injector machine cutting torch MSZ 832/110-PMYF for fuel gas propane and natural gas: 716.51788

Adjusting valve for heating oxygen, G 1/4 RH: 718.00500 Adjusting valve for cutting oxygen, G 3/8 RH: 718.00501 Adjusting valve for fuel gas G 3/8 LH: 718.00502

Flashback arrestor for heating oxygen, G 1/4 RH: 0.463.389 Flashback arrestor for cutting oxygen, G 3/8 RH: 0.463.384 Flashback arrestor for fuel gas, G 3/8 LH: 0.463.388

Extended rack bar: 716.51791

Counter weight : 716.51792

Circle cutting attachment, diameter 30-2400mm / 1.2-96“: 716.51793

Standard hose package, 730 mm: 716.51929

Extended hose package, 950 mm: 716.51930

Cross feed torch holder for strip and multi bevel cuts 716.51794

Portable gas cutting machine

Cylinder regulators

Torch kit system

Accessories