Durable and efficient spare parts and consumables are the main topic of Kjellberg Finsterwalde's research and development work. The ongoing optimisation of the production process and extensive new developments are the basis for highest cutting quality and the consistent reduction of costs per cutting metre. This technology is summarised under one name: YellowXLife®. The user will benefit from longer lifetimes which lead to a further reduction of costs because less consumables are needed and, above all, the change times will be reduced as well. Thus, a higher yield per piece of consumables is achieded or, respectively, a reduction of the costs per cutting metre.

With the YellowXLife® cosumables for cutting with oxygen with HiFocus and FineFocus the user benefits from the following advantages:

Complete range of spares and consumables of all Kjellberg plasma models are available with us

High-precision cutting and marking from 0.5 mm to 160 mm

High-precision cutting and marking from 1 mm to 100 mm

Precise cutting from 3 mm to 160 mm

Robust systems for simple applications from 3 mm to 70 mm

Cost-efficient starter models from 1 mm to 20 mm

Kjellberg's systems for manual plasma cutting can be used for many applications. According to the customers' preferences there are diverse systems which are perfectly tailored to their individual requirements.

Mobile cutting inverter

Manual cutting and plasma gouging

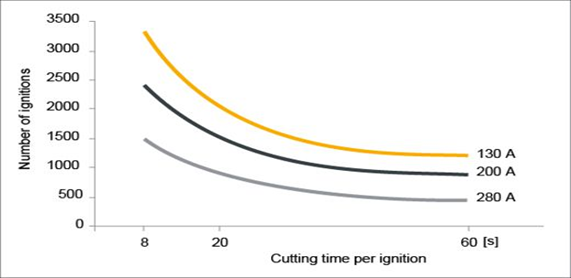

For cutting mild steel with plasma cutting units of the HiFocus neo series robust copper cathodes are available that convince with a long consumable life and an excellent price-performance ratio. Thus, expensive downtimes for changing the consumables are reduced.

Thanks to a consumable upgrade also users with older HiFocus units may benefit from powerful copper cathodes for cutting mild steel. There is no modification of hardware required. Customers with the plasma torches PerCut 200/201/2010/211 or PerCut 440/450/451 can exchange easily their former cathodes for new copper cathodes.

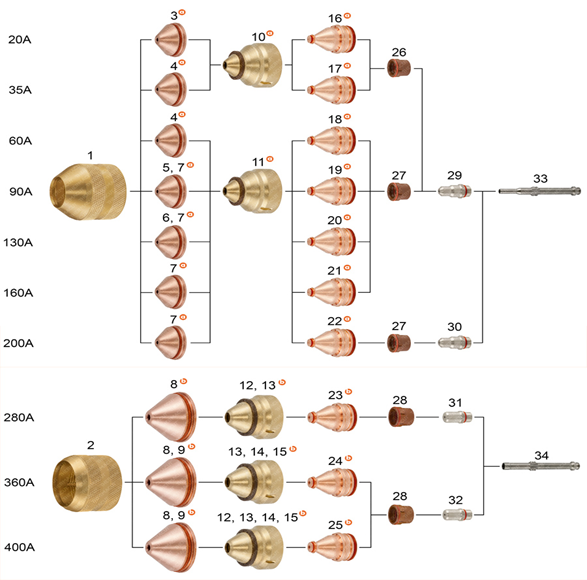

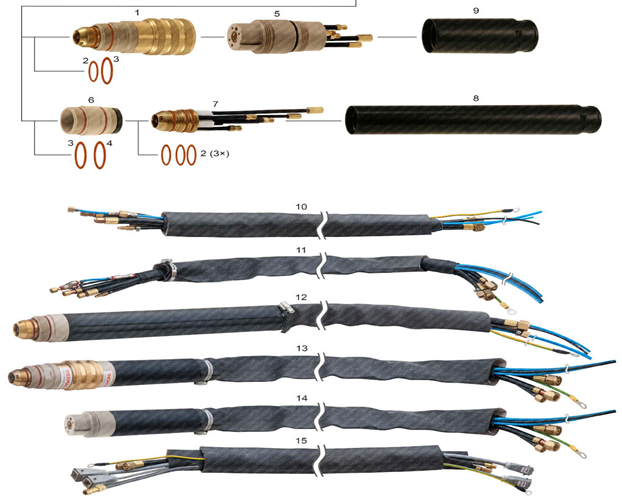

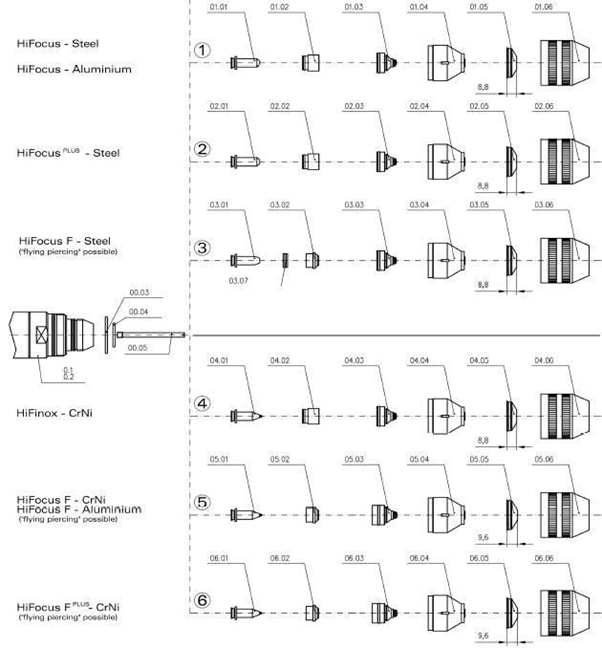

Consumables

The CUTi 35C is the smallest manual plasma cutting unit of this product line and has an integrated compressor. With this own and independent compressed air supply, the CUTi 35C cuts materials with a thickness of up to 6 mm. If an external compressed air supply is available the possible cutting current increases from 25 A to 35 A thereby also increasing the material thickness to 10 mm. The integrated air supply and the 230 V connection guarantee highest mobility. Its low weight of only 12.5 kg is also impressive.

| Power Source | CUTi 35C |

| Mains voltage | 1x 230 V | >

| Cutting current | 15 A - 35 A (25% duty cycle) - max. 25 A with integrated compressor 20 A (100% duty cycle) |

| Cutting range | up to 6 mm (with internal compressor) up to 10 mm (with compressed air supply) |

| Dimensions (L x W x H) | 550 x 150 x 245 mm |

| Weight | 12.5 kg |

| Plasma torch | PHT 25 |

The manual plasma cutting inverter CUTi 35 can be used for cutting electrically conductive materials, e.g. aluminium, copper, mild steel and stainless steel with a thickness of up to 12 mm. The sinusoidal power consumption with PFC (power factor correction) guarantees the maximum utilization of power of the single-phase 230 V mains. The permanently connected hand torch of the type KjellCut 35C is ignited by means of a drawn pilot arc without work-piece contact.

Due to its compact design and light weight of only 10 kg (including torch) the plasma cutting unit can easily be transported and is suited for mobile use in production and workshops as well as for repairing and servicing. A large variety of accessories, among others wheelguide, long consumables or circle cutting devices for straight and contour cutting and of holes and circles, extends the range of possible applications.

| Power Source | CUTi 35 |

| Mains voltage | 1x 230 V | >

| Cutting current | 35 A (40 % duty cycle) 28 A (60 % duty cycle) 22 A (100 % duty cycle) |

| Cutting range | recommended: 10 mm maximal: 12 mm |

| Dimensions (L x W x H) | 480 x 150 x 225 mm |

| Weight | 10 kg |

| Plasma torch | KjellCut 35C |

The CUTi 70 is a small manual plasma cutting unit for a cutting range up to 30 mm. Its high performance and low weight of only 16.4 kg guarantee highest flexibility. It is ideally suitable for industry, craft and in workshops.

| Power Source | CUTi 70 |

| Mains voltage | 3x 400 V | >

| Cutting current | 70 A (35% duty cycle) 50 A (100% duty cycle) |

| Cutting range | up to 30 mm |

| Dimensions (L x W x H) | 470 x 180 x 250 mm |

| Weight | 16.4 kg |

| Plasma torch | KjellCut 70 |

The CUTi 90 is a manual plasma cutting unit with small dimensions with a cutting range of up to 35 mm material thickness. Its high performance and low weight of only 17 kg guarantee highest flexibility. The CUTi 90 is ideally suited for use in industry, craft and in workshops.

| Power Source | CUTi 90 |

| Mains voltage | 3x 400 V | >

| Cutting current | 90 A (40% duty cycle) 55 A (100% duty cycle) |

| Cutting range | up to 35 mm |

| Dimensions (L x W x H) | 470 x 180 x 270 mm |

| Weight | 17 kg |

| Plasma torch | KjellCut 120 |

The CUTi 120 is the most powerful unit of this product line with a cutting range of up to 50 mm material thickness. It offers enormous performance combined with portability which makes it ideally equipped for heavy use and simple applications. It is excellently suitable for use in industry, craft and in workshops.

| Power Source | CUTi 120 |

| Mains voltage | 3x 400 V | >

| Cutting current | 120 A (35% duty cycle) 80 A (100% duty cycle) |

| Cutting range | up to 50 mm |

| Dimensions (L x W x H) | 610 x 230 x 410 mm |

| Weight | 28.5 kg |

| Plasma torch | KjellCut 120 |

The liquid-cooled CUTLINE 20W is recommended for frequent or regular plasma cutting applications up to 20 mm material thickness. Further, it is optionally available with a 400 V or 230 V connection. Due to the direct cooling of the consumables, the lifetime of nozzles and cathodes is five times higher.

| Power Source | CUTLINE 20W* |

| Cutting current | 25 A / 50 A (step-switched) |

| Cutting range | 1 - 20 mm |

| Dimensions (L x W x H) | 670 x 490 x 880 mm |

| Weight | 84 kg |

| Plasma torch | PHT-30 W/L |

The liquid-cooled CUTLINE 40W is recommended for frequent or regular applications with a cutting range up to 40 mm material thickness. Due to the direct cooling of the consumables the liftetime of the nozzles and cathodes is five times higher.

Additionally, the CUTLINE 40W offers a plasma gouging function - a clean alternative to gouging with carbon electrodes.

| Power Source | CUTLINE 40W* |

| Cutting current | 50 A / 100 A (step-switched) |

| Cutting range | 1 - 40 mm |

| Dimensions (L x W x H) | 820 x 490 x 880 mm |

| Weight | 132 kg |

| Plasma torch | PHT-45 W/L |

Manual plasma cutting

The HiFocus 80i is the smallest high-precision plasma cutting unit worldwide. It covers a cutting range from 0.5 mm to 25 mm. It provides highest quality when cutting thin and medium-sized sheets with an unbeatable price-performance ratio. A wide range of special torches and various fields of application in connection with robot systems make it ideal for the automotive industry.

| Power source | HiFocus 80i |

| Mains voltage* | 3x 400 V, 50 Hz |

| Cutting current at 100% duty cycle | 10 - 80 A |

| Cutting range | 0.5 - 25 mm |

| Piercing | up to 15 mm |

| Dimensions (L x W x H) | 1000 x 510 x 1020 mm |

| Weight | 161 kg |

| Plasma torch | PerCut 80/90 |

| *Other voltages and frequencies on request. |

The HiFocus 130 neo is a flexible high-performance and high-precision plasma cutting unit. It covers a cutting range from 0.5 mm to 40 mm. The HiFocus 130 neo provides highest quality when cutting thin and medium-sized sheets with an unbeatable price-performance ratio. A wide range of special torches and various fields of application in connection with robot systems make it ideal for the automotive industry.

Furthermore, the HiFocus 130 neo can be used for the marking of materials.

With HiFocus neo the user benefits from high speed when cutting and marking electrically conductive materials, ensuring at the same time excellent quality and low process costs. Thanks to optimised technology, the consumables are protected and the plasma cutting process is more efficient.

The HiFocus 130 neo is available as standard with the new Contour Cut Technology for cutting fine inner and outer contours and small holes in mild steel.

| Power source | HiFocus 130 neo |

| Cutting current at 100 % duty cycle | 20 - 130 A |

| Marking current | 16 A |

| Cutting range | 0.5 - 40 mm |

| Piercing | up to 25 mm |

| Dimensions (L x W x H) | 960 x 540 x 1050 mm |

| Mass | 251 kg |

| Plasmabrenner | PerCut 201/211 |

The HiFocus 161i neo is the latest high-precision plasma cutting system for the cutting range between 0.5 mm and 50 mm. Equipped with the soft-switch inverter technology, it offers a wide range of possibilities for cutting and marking thin and medium-sized sheets. It meets the requirements of the metal and container construction industries, the engineering and automotive industries and many other sectors. The HiFocus 161i neo can be combined with 2D as well as 3D CNC-controlled guiding systems, i.e. gas cutting systems, robots and pipe cutting systems.

With HiFocus neo the user benefits from high speed when cutting and marking electrically conductive materials, ensuring at the same time excellent quality and low process costs. Thanks to optimised technology, the consumables are protected and the plasma cutting process is more efficient

The HiFocus 161i neo is available as standard with the Contour Cuttechnology for cutting fine inner and outer contours and small holes in mild steel.

| Power source | HiFocus 161i neo |

| Mains voltage* | 3x 400 V, 50 Hz |

| Cutting current at 100 % duty cycle | 10 - 160 A |

| Marking current | 5 - 25 A |

| Cutting range | 0.5 - 50 mm |

| Piercing | up to 30 mm |

| Dimensions (L x W x H) | 985 x 570 x 1140 mm |

| Mass | 206 kg |

| Plasmabrenner | PerCut 201/211 |

| *Other voltages and frequencies on request. |

The HiFocus 280i neo is one of the most flexible and most powerful high-precision plasma cutting units. It covers a cutting range from 0.5 mm to 70 mm. The latest inverter technology allows the highest marking quality and functionality on the market. The HiFocus 280i neo is ideally suited for steel service centers, steel producers and distributors.It can be combined with 2D or 3D cnc-controlled guiding systems like gas cutting machines, robots and pipe cutting machines.

With HiFocus neo the user benefits compared to the competitors from higher speed when cutting and marking electrically conductive materials, ensuring at the same time excellent quality and low process costs. Thanks to optimised technology, the consumables are protected and the plasma cutting process is more efficient.

The HiFocus 280i neo is available as standard with the Contour Cut Technology for cutting fine inner and outer contours and small holes in mild steel.

| Power source | HiFocus 280i neo |

| Mains voltage* | 3x 400 V, 50 Hz |

| Cutting current at 100 % duty cycle | 280 A |

| Marking current | 5 - 50 A |

| Cutting range | 0.5 - 70 mm |

| Piercing | up to 40 mm |

| Dimensions (L x W x H) | 1030 x 680 x 1450 mm |

| Mass | 505 kg |

| Plasmabrenner | PerCut 451 |

| *Other voltages and frequencies on request. |

The HiFocus 360i neo is one of the most flexible and most powerful high-precision plasma cutting units. Its wide cutting range from 0.5 mm to 80 mm means a considerably higher flexibility. The latest inverter technology allows the highest marking quality and functionionality on the market. The HiFocus 360i neo is ideally suited for steel service centers, steel producers and distributors because it can be combined with 2D or 3D CNC-controlled guiding systems like gas cutting machines, robots and pipe cutting machines.

With HiFocus neo the user benefits compared to the competitors from higher speed when cutting and marking electrically conductive materials, ensuring at the same time excellent quality and low process costs. Thanks to optimised technology, the consumables are protected and the plasma cutting process is more efficient.

The HiFocus 360i neo is also available for underwater cutting.

The HiFocus 360i neo is available as standard with the Contour Cut Technology for cutting fine inner and outer contours and small holes in mild steel.

| Power source | HiFocus 360i neo |

| Mains voltage* | 3x 400 V, 50 Hz |

| Cutting current at 100 % duty cycle | 360 A |

| Marking current | 5 - 50 A |

| Cutting range | 0.5 - 80 mm |

| Piercing | up to 50 mm |

| Dimensions (L x W x H) | 1030 x 680 x 1450 mm |

| Mass | 517 kg |

| Plasmabrenner | PerCut 451 |

| *Other voltages and frequencies on request. |

The HiFocus 440i neo is one of the most flexible and most powerful high-precision plasma cutting units worldwide. Its wide cutting range from 0.5 mm to 120 mm i means considerably higher flexibility. The latest inverter technology allows the highest marking quality and functionality on the market. The HiFocus 440i neo is ideally suited for steel service centers, steel producers and distributors.

With HiFocus neo the user benefits compared to the competitors from higher speed when cutting and marking electrically conductive materials, ensuring at the same time excellent quality and low process costs. Thanks to optimised technology, the consumables are protected and the plasma cutting process is more efficient.

The HiFocus 440i neo is also available for underwater cutting.

The HiFocus 440i neo is available as standard with the Contour Cut Technology for cutting fine inner and outer contours and small holes in mild steel.

| Power source | HiFocus 440i neo |

| Mains voltage* | 3x 400 V, 50 Hz |

| Cutting current at 100 % duty cycle | 440 A |

| Marking current | 5 - 50 A |

| Cutting range | Mild steel: 0.5 - 120 mm EStainless steel: 1.0 - 120 mm |

| Piercing | up to 50 mm |

| Dimensions (L x W x H) | 1030 x 680 x 1450 mm |

| Mass | 589 kg |

| Plasmabrenner | PerCut 451 |

| *Other voltages and frequencies on request. |

The plasma cutting system HiFocus 600i neo sets new standards for plasma cutting: Materials with a thickness of up to 160 mm can be cut precisely. Furthermore the system is suited for marking, bevel and underwater cutting.

Consisting of two power sources (HiFocus 360i neo, Power Model HiFocus 600i neo) the system achieves a maximum cutting current of 600 A and can be adapted to guiding systems.

With HiFocus neo the user benefits compared to the competitors from higher speed when cutting and marking electrically conductive materials, ensuring at the same time excellent quality and low process costs. Thanks to optimised technology, the consumables are protected and the plasma cutting process is more efficient.

The plasma cutting system HiFocus 600i neo uses the approved Contour Cut technology for cutting contours, holes and webs fast and precisely in mild steel.

| Power source | HiFocus 360i neo | Power Modul HiFocus 600i neo |

| Mains voltage* | 3x 400 V, 50 Hz | 3x 400 V, 50 Hz |

| Cutting current at 100 % duty cycle | 10-360 A | 100-300 A |

| Marking current | 5 - 50 A | |

| Cutting range | 0.5-160mm | |

| *Other voltages and frequencies on request. |

With just a few settings the new plasma cutting units of the Smart Focus series achieve excellent results in the cutting range from 1 to 100 mm. Even under challenging conditions highest cutting quality and speed are realised. Therefore we use our proven cutting technologies as for example Contour Cut for cutting mild steel. The optimised gas control units and torches protect the consumables, reduce the gas consumption and the costs per cutting metre.

The FineFocus 450 is the reasonably-priced starter model of the FineFocus series. It offers good cutting results on medium-sized sheets and high flexibility due to the optional use of air, oxygen, argon and hydrogen. This extremely robust plasma unit cuts all electrically conductive materials with a thickness from 3 mm to max. 45 mm.

| Power source | FineFocus 450 |

| Cutting current | 40-130 A | >

| Cutting range | 3-45mm |

| Piercing | uo to 25 mm |

| Dimensions (L x W x H) | 1025 x 711 x 970 mm |

| Weight | 251 kg |

| Plasma torch | PB-S47 W |

The FineFocus 600 is the latest plasma cutting unit of the FineFocus series. It offers good cutting results on medium-sized plates and high flexibility due to the optional use of air, oxygen, argon and hydrogen. With its excellent price-performance ratio and outstanding cutting speeds, it is especially suited for all metal-working branches of industry, e.g. steel and metal construction, shipbuilding and also metal service centres. This extremely robust unit cuts all electrically conductive materials with a thickness from 3 mm to max. 60 mm.

| Power source | FineFocus 600 |

| Cutting current at 100% duty | 40-130 A | >

| cycle | 3 - 60 mm |

| Cutting range | up to 30 mm |

| Piercing | |

| Dimensions (L x W x H) | 980 x 644 x 1320 mm |

| Weight | 365 kg |

| Plasma torch | PB-S60 W |

| Power source | FineFocus 800 |

| Cutting current at 100% duty | 80-300 A | >

| cycle | Dry cutting: 5 - 80 mm |

| Cutting range | Underwater cutting: 5 - 40 mm up to 40 mm |

| Piercing | |

| Dimensions (L x W x H) | 1375 x 870 x 1505 mm |

| Weight | 556 kg |

| Plasma torch | PB-S80 W |

The FineFocus 1600 consists of two FineFocus 800 power sources connected in parallel. It cuts materials with a thickness of up to 160 mm (dry plasma cutting) or, respectively, up to 100 mm (under water plasma cutting). Furthermore, it is possible to use two plasma torches PB-S80 W (up to 300 A) simultaneously.

| Power source | FineFocus 1600 (2x FineFocus 800) |

| Cutting current at 100% duty cycle | 40-600 A | >

| Cutting range | Dry plasma cutting: 5 - 160 mm Underwater plasma cutting: 5 - 100 mm |

| Piercing | up to 80 mm |

| Dimensions (L x W x H) | 2x 1375 x 870 x 1505 mm |

| Weight | 2x 552 kg |

| Plasma torch | Dry / underwater PB-S80 W Dry PB-S151 W Underwater PB-S100 WU |

The plasma cutting unit PA-S45 W is the allrounder of the PA-S series. It offers the right package for the majority of simple cutting tasks and covers a cutting range from 3 mm up to 45 mm. In addition to the well-proven torch PB-S45 W for air, oxygen and argon/hydrogen, the PB-S44 W with swirl gas function for air as plasma gas is also available as an alternative. This torch increases the piercing capacity and process stability for many simple applications. In addition to machine torches, the PA-S45 W can also be operated with hand torches including a gouging option.

| Power source | PA-S45 W |

| Cutting current at 100% duty cycle | 45 A / 85 A / 130 A | >

| Cutting range | 3 - 45 mm |

| Piercing | up to 20 mm |

| Dimensions (L x W x H) | 950 x 710 x 1020 mm |

| Weight | 240 kg |

| Plasma torch | Machine torches PB-S45 W PB-S44 W PB-S45 WH Hand torch |

The plasma cutting unit PA-S70 W is the most powerful model of the PA-S series. It covers a cutting range from 5 up to 70 mm. In addition to the cost-efficient use of air as plasma gas, argon/hydrogen can be used in order to achieve better cutting results with stainless steel. In addition to the machine torch, the unit can also be operated with a hand torch including a gouging option.

| Power source | PA-S70 W |

| Cutting current | 80 A / 160 A / 240 A | >

| Cutting range | 5 - 70 mm |

| Piercing | up to 30 mm |

| Dimensions (L x W x H) | 1380 x 870 x 1080 mm |

| Weight | 460 kg |

| Plasma torch | Machine torches PB-S70 W Hand torch PB-S70 WH |

The plasma cutting inverter CutFire 65i is a powerful, reliable plasma unit for cutting thin sheets up to 12 mm thickness. Due to its compact design and easy handling the inverter is suited for cutting task in heating, ventilation and pipeline engineering as well as in the light industry.

The plasma cutting inverter can be adapted to existing guiding systems or used with a hand torch. The CutFire 65i is equipped with air-cooled torch technique and uses air as cost-efficient plasma gas.

| Power source | CutFire 65i |

| Cutting current at 100% duty cycle | 50 A | >

| Cutting range | recommended: to 8 mm >br> maximum: to 12 mm |

| Dimensions (L x W x H) | 470 x 180 x 270 mm |

| Weight | 17 kg |

| Machine torch | Flash 100 |

| Hand torch | KjellCut 70 |

The CutFire 100i is a powerful plasma unit with air as plasma gas. It offers a wide range of applications at low investment costs. It is equipped with the latest inverter technology and is the only air-cooled system on the market that offers a duty cycle of 100%.

The cutting inverters CutFire 100i built in or after 2017 are equipped with the new machine torch Flash 101. With its new consumables the torch uses air as swirl gas.The air rotating around the plasma arc stabilizes the arc and thus enables piercing up to 20 mm. The cooling and protective effect of the swirl gas ensures higher cutting speeds and an increased lifetime of the consumables.

The CutFire 100i is ideally suited for cutting thin sheets in ventilation and switch cabinet construction, in metal construction and many other craftsmen businesses, industrial and production plants.

| Power source | CutFire 100i |

| Cutting current at 100% duty cycle | 100 A | >

| Cutting range | 1 - 30 mm (built in or after 2017) |

| Piercing | up to 20 mm (built in or after 2017) |

| Dimensions (L x W x H) | 710 x 280 x 590 mm |

| Weight | 50 kg |

| Plasma torch | Flash 100 Flash 101 (for CutFire 100i built in or after 2017) |

The marking of materials is relevant for a number of applications. These include for example markings for subsequent manufacturing processes like punch marks for borings, scribing marks for subsequent cutting processes or marking of part numbers. It is an advantage that the marking depth is manually adjustable. In addition to temper colours which are not visible anymore after finishing, you can also produce deep markings which are visible even after colouring.

With the FineMarker we offer you an external unit which can easily be integrated into your present cutting system, no matter whether it is an older plasma or an oxy-fuel cutting system.

| Output current | 4 - 25 A |

| Duty cycle | 100% | >

| Weight | 30kg |

| Dimensions (L x W x H) | 710 x 400 x 440 mm |

| Marking gases | Argon or air |

| Marking speed | 1.5 - 12 m/min |

| Plasma torch | PB-M25 W (liquid-cooled) |

Mechanized plasma